The Product Range

Fast docking equipment for geater efficiency at shipyards.

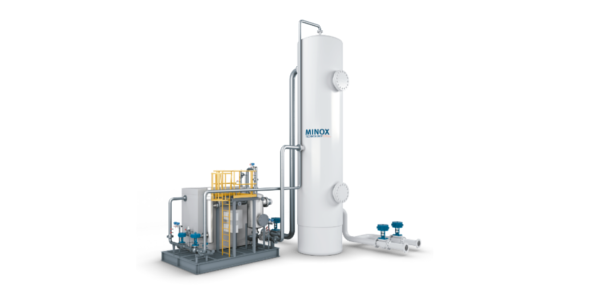

Minox®Compact - 2-Stage de-oxygenation process of sea-water

A key process feature is the method of contacting the nitrogen stream with the water in static

mixers where co-current turbulent flow is achieved, producing highly efficient mixing of water &

gas, simultaneously striping the disolved oxygen from the water - to very low concentrations.

Does not require any scavenger chemicals.

The low system weight combined with flexible

and skid mounted design allows for efficient tailoring in accordance to the customers'

specifications. Each unit can be tailor made to fit into a given space which makes it possible

to install on existing platforms, or when conventional deaeration systems are being upgraded. In

such cases, the process will not only enable injection water volumes to be increased with a

reduced oxygen content, but the need for scavenger chemicals is eliminated or greatly reduced,

as well as saving fuel gas for stripping.

The Minox®Tower

Based upon the same basic principle of cycling & purifying nitrogen gas, this system offers a

competitive alternative to vaccum & fuel gas de-aerators, yielding a very low residual O2

content. In this system the contacting between the nitrogen stream & the water is done through

counter-current flow over a packed bed of structured packing. The system can operate under

atmospheric, or a few bar pressure. The danger related to using natural gas as stripping gas is

removed.

It is even possible to convert exisiting vaccum or fuel gas towers into

Monox®Tower and makes it possible to increase water flow through the tower. The system

allows for a residual O2 content down to 20 ppb or less, without applying scavenger chemicals.