Nel Hydrogen with more than 3,500 reliable, cost-efficient electrolysers installed around the globe, is the recognized industry leader of Alkaline and PEM water electrolysers.

Since their founding in 1927, sustained R&D efforts have contributed to continual improvement of electrolyser technology, setting the benchmark in the market. NEL’s electrolysis technology is today widely respected for its robustness, reliability and energy efficiency.

NEL’s water electrolysers make a superior choice for Industry, Transport and Power-to-X applications. Multiple, scalable, flexible, modular product ranges are set to meet any customer requirements.

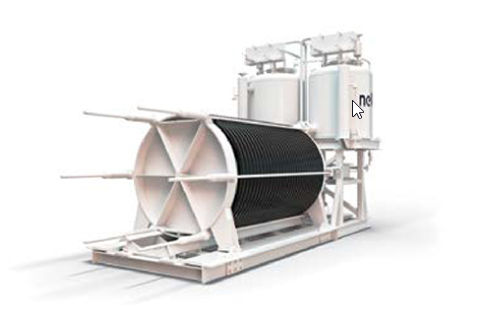

Large Scale H2 Plants: Large capacity at minimum footprintWhether you need large quantities of hydrogen for industrial purposes, or utilization of excess renewable energy for energy storage – we have experience in both fields.

The very nature of the A Series is seamless capacity upsizing from medium to large scale H₂ plants based on water electrolyser technology. NEL’s experience in large scale plants is exemplified through historical plants exceeding 30,000 Nm³/h, as well as the recent installation of new plants with an energy capacity of more than 60 MW

Norinco Private Limited represents NEL, Norway, the leading supplier for alkaline water electrolysis-based hydrogen generation plants catering to conventional industry sectors as well as mega requirements of upcoming opportunities in green energy applications

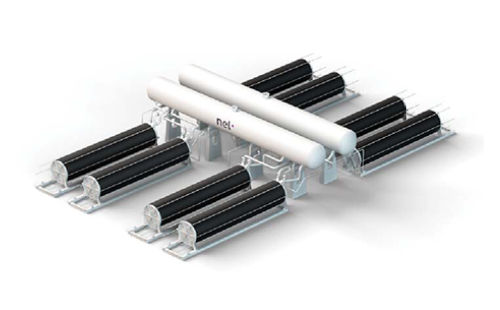

Atmospheric Alkaline Electrolysers: The A Series represents the most reliable and efficient electrolysers in the world. Our modular concept enables us to deliver customized indoor hydrogen solutions for any application, configuration and size – anywhere. Nel Hydrogen tailors each delivery to any customer requirement, from complete installation of the entire electrolyser plant, to delivery of specific modules according to customer preferences

Standard Electrolyser: 50 to 485 Nm3/h

Electrolysers in tandem: up to 3880 Nm3/h

| Oil: | hydrogenation processes, fat hardening |

| Chemical: | ammonia, hydrogen peroxide, methanol, phenol, |

| Petrochemical: | purified terepthalic acid (PTA) |

| Fertiliser: | ammonia production |

| Steel: | annealing and galvanization in steel sector |

| Solar: | photovoltaic grade wafer production |

| Optic fibre: | oxy-hydrogen burners |

| Float glass, tools: | protective atmosphere |

| Semiconductor: | carrier gas in thin film deposition Select Photos |

| Transport: | replacing fossil fuels |

| Steel and others: | replacing fossil fuels |

| Power: | green power, integration with solar, wind, biogas power grids |